Modular Mooring Buoys

Subsea Modular Mooring Buoys

In shallow or deepwater there will always be a requirement to safely moor a floating structure, it may be an oil tanker, production vessel, a semi-submersible drilling rig or deepwater platform. In most cases this mooring requirement will include chains, wire ropes and one or more subsea mooring or spring buoys.

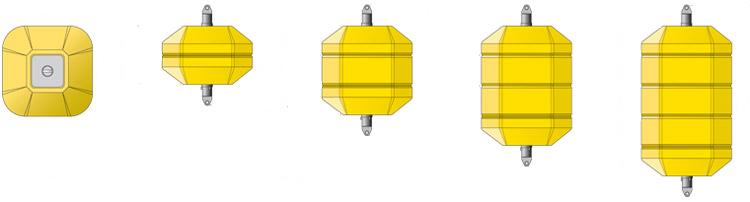

Evergreen Subsea Mooring Buoys are available in a wide range of sizes and water depths, both in modular and non-modular form (one-piece buoy), and in custom and standard configurations.

Typical mooring buoys consist of a steel thru-member and end fittings and a number of modular buoyancy elements. Elements can be added or removed to adjust the amount of buoyancy required. Alternatively, one piece buoys can be manufactured with integral thru-members.

Pipeline deployment buoys for shore-pull and deepwater J-Lay and laybarge applications can be supplied in a range of buoyancy and depth rating configurations, from surface to deep water.

Specification List:

Designed for deployment in depths of 0-2000msw these mooring buoys are used predominantly as suspended moorings or subsea markers. This range is highly adaptable and can be fitted with a wide range of end fittings.

| Mini Modular Mooring Buoys | ||||||||

|

|

Weight in air (kg) |

Nominal buoyancy(kg) |

Weight in air (kg) |

Nominal buoyancy(kg) |

Weight in air (kg) |

Nominal buoyancy(kg) |

Weight in air (kg) |

Nominal buoyancy(kg) |

|

Surface |

746 |

7674 |

1051 |

3226 |

1356 |

4779 |

1661 |

6331 |

|

250msw |

1205 |

1215 |

1881 |

2396 |

2558 |

3577 |

3234 |

4758 |

|

500msw |

1356 |

1064 |

2154 |

2123 |

2953 |

3182 |

3752 |

4241 |

|

1000msw |

1501 |

919 |

2416 |

1861 |

3332 |

2802 |

4248 |

3744 |

|

1500msw |

1490 |

848 |

2398 |

1763 |

3306 |

2679 |

4213 |

3594 |

|

2000msw |

1539 |

799 |

2487 |

1675 |

3434 |

2550 |

4381 |

3426 |

|

End module : |

L: 1750mm. W: 1750mm. H: 530mm; Nominal net buoyancy: 750kg | |||||||

|

Centre module : |

L: 1750mm. W: 1750mm. H: 670mm; Nominal net buoyancy: 1000kg | |||||||

| Standard Modular Mooring Buoys | ||||||||

|

|

Weight in air (kg) |

Nominal buoyancy(kg) |

Weight in air (kg) |

Nominal buoyancy(kg) |

Weight in air (kg) |

Nominal buoyancy(kg) |

Weight in air (kg) |

Nominal buoyancy(kg) |

|

Surface |

1773 |

6968 |

2396 |

10421 |

3020 |

13874 |

3644 |

17326 |

|

250msw |

3526 |

5215 |

4977 |

7841 |

6427 |

10467 |

7877 |

13093 |

|

500msw |

4103 |

4638 |

5825 |

6992 |

7547 |

9347 |

9270 |

11701 |

|

1000msw |

4656 |

4084 |

6639 |

6178 |

8622 |

8272 |

10605 |

10365 |

|

1500msw |

4617 |

3949 |

6582 |

6020 |

8547 |

8091 |

10511 |

10162 |

|

2000msw |

4804 |

3762 |

6857 |

5745 |

8910 |

7728 |

10963 |

9710 |

|

End module : |

L: 2345mm. W: 2345mm. H: 1100mm; Nominal net buoyancy: 2800kg | |||||||

|

Centre module : |

L: 2345mm. W: 2345mm. H: 800mm; Nominal net buoyancy: 2500kg | |||||||

| Mega Modular Mooring Buoys | ||||||||

|

|

Weight in air (kg) |

Nominal buoyancy(kg) |

Weight in air (kg) |

Nominal buoyancy(kg) |

Weight in air (kg) |

Nominal buoyancy(kg) |

Weight in air (kg) |

Nominal buoyancy(kg) |

|

Surface |

3688 |

15458 |

4902 |

22553 |

5839 |

29239 |

7191 |

36098 |

|

250msw |

7575 |

11571 |

10489 |

16966 |

13126 |

21951 |

16179 |

27110 |

|

500msw |

8854 |

10293 |

12327 |

15128 |

15523 |

19554 |

19134 |

24254 |

|

1000msw |

10080 |

9066 |

14090 |

13365 |

17823 |

17255 |

21971 |

21318 |

|

1500msw |

9994 |

8733 |

13966 |

12955 |

17937 |

17179 |

21909 |

21398 |

|

2000msw |

10409 |

8319 |

14562 |

12359 |

18715 |

16399 |

22868 |

20439 |

|

End module : |

L: 3000mm. W: 3000mm. H: 1400mm; Nominal net buoyancy: 5600kg | |||||||

|

Centre module : |

L: 3000mm. W: 3000mm. H: 1000mm; Nominal net buoyancy: 5000kg | |||||||

Materials:

Syntactic Foam Core

The core of each riser buoyancy module is manufactured from a proprietary, lightweight, high density composite syntactic core ( 0.20~0.70 g/cm3).

Composite foam cores are a combination of depth rated syntactic foam that encapsulates seamless

composite spheres.The resulting material exhibits low density, high compressive strength and low levels

of water ingress at the design water depths.

Shallow Water Applications

In shallow water applications, other materials such as steel and FRP tubular buoyancy elements can be utilized. The use of these materials is determined by an engineering analysis which selects the most appropriate material solution for the application.

Skin System:

A variety of protective outer skins is available, such as integrally moulded FRP, elastomeric urethane and marine grade thermoplastics. In the case of FRP skin, the system is finished with a two-pack marine grade epoxy paint.

Steelwork:

All Evergreen subsea mooring buoys have a central steel tubular member around which fits the buoyancy module. Various end fittings are available including pad eyes, swivel assemblies,anchor handling crosses or ROV friendly connection systems.

All Evergreen steelwork is shot blasted and coated with a coal tar epoxy paint finish. A suitable cathodic protection system can be provided if required.

>> To get more information, please feel free to contact us.